Die 5 wichtigsten versteckten Ursachen für Ausfälle von Industriepumpen

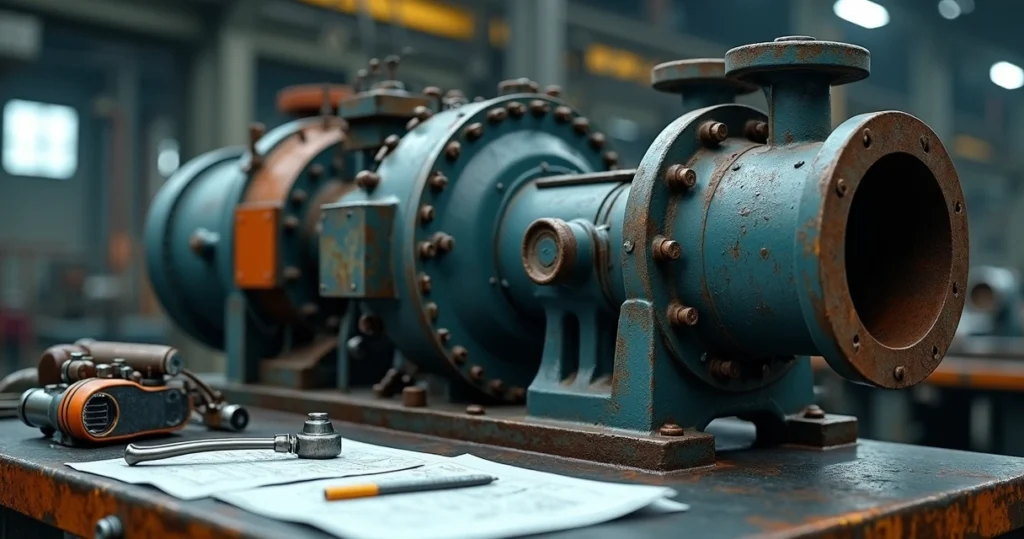

Pumps rarely draw attention when they work as expected. They sit, they hum, they move liquid, and very few passersby would even glance their way. But behind the gentle patience of their routine, problems can take root in silence. Weeks or months may pass before anything feels wrong—a leak here, a rattle there, or perhaps nothing but numbers shifting quietly outside tolerance. Hidden causes thrive in this space, slowly pushing even the best equipment closer to unexpected stops. In nearly every case, there’s a story underneath the surface. This article shares five of the main hidden causes that can bring pumps in industrial settings to a halt, often without warning.

Component wear—hidden until it’s too late

Component wear—hidden until it’s too late

Nothing lasts forever, especially parts that move. Inside a pump, components like rotors, volutes, shafts, and bearings slowly wear down. But the tricky thing? Most damage here grows in tiny increments. No loud snaps. No flashing lights. Just gradual loss.

Studies have shown that this slow wear often springs from tiny solid particles—grains, debris—slipping past filters or being present in the fluid from the start. Over time, their constant friction erodes internal parts. This eats away at the performance of pumps, makes them run harder, and sets the stage for unexpected failure. Sometimes, efficiency drops so subtly that operators won’t realize until major repairs are needed.

A worn rotor rarely shouts. But it leaves clues if you look closely.

I’ve seen cases where nothing looked wrong, but a slight vibration kept creeping back after each restart. Only after disassembling the unit did a technician reveal rotors scored by years of minuscule impacts. Once visible, the damage seemed obvious. Until then? Completely hidden. This is why Prelix uses its data analysis to look for odd, recurring patterns—early warnings a pump can’t voice directly.

Contamination—what you don’t see can destroy you

Contamination seems so small. A drop of water, a fleck of rust, a few bits of dust. Yet these are often the real enemies inside pumps. As fluid moves through systems, it picks up the world around it—metal shavings, sand, oils, stray fibers. If the pump’s seals or filters are less than perfect, or if fluid isn’t changed routinely, the accumulation quietly shortens the life of seals, bearings, and everything else in the flow path. Symptoms like louder operation or slower pressure build-up may not even appear before a pump stops—or worse, fails catastrophically.

- Solid debris grinds against smooth surfaces, ruining tolerances.

- Water increases corrosion, attacking both metal and polymer components.

- Contaminants may clog tight passages, raising pressure until a seal cracks.

Industry research from one major hydraulics provider puts contamination as a factor in 70 to 80 percent of all failures—a quietly alarming figure. Catching this early isn’t always easy, which is why regular oil analysis and system monitoring, as done by Prelix, pay off by flagging unseen problems before they cut production. You may not spot a single particle, but their impact is very real.

Cavitation—the silent destroyer

This one sounds like a science experiment, yet it happens in industrial plants every week. Cavitation occurs when pressure drops low enough to let vapor bubbles form and then collapse violently inside the pump. Unlike air—a constant, gentle presence—these bubbles hit like tiny hammers, leaving pitting and scars on metal surfaces. At first, it’s almost impossible to notice. Operations continue, operators walk by, nothing changes. But over time, the rotor edges soften, surfaces turn rough, and efficiency tumbles. Eventually, the pump—a machine meant to move liquid—begins to shake itself apart.

Cavitation is quiet until it’s not. By then, serious damage is done.

As detailed in technical analysis of pump failures, this process can be hard to link directly to visible symptoms before components are deeply compromised. Subtle sounds, a high-pitched hiss, or slightly reduced throughput are easy to overlook. I’ve personally heard that faint, metallic noise that’s so different from normal operation—not everyone would notice, but for those who do, it’s a signal to stop and investigate. Systematic monitoring, like that enabled by Prelix, can spot trends hinting at cavitation, so root causes don’t remain invisible for long.

Seal and bearing troubles—problems that hide in plain sight

Seal and bearing troubles—problems that hide in plain sight

Seals dry out, bearings crack, and oil finds its way where it shouldn’t go. More often than not, these simple parts are responsible for breakdowns. But unlike catastrophic shaft snaps or motor overloads, seal and bearing problems don’t always leap to the eye. Recent industry surveys say more than 60 percent of pump failures trace back to such issues—often acting quietly, slowly. A bearing may run hot, but just a little at first. A seal might drip intermittently, almost invisible against a damp floor.

Operators may wipe away a drop or ignore a squeak—routine, perhaps, or easy to put off for another day. Until, that is, a rush of fluid signals full failure. The story here is absence: the absence of clear, immediate signs. This is why keeping records, tracking vibration, and listening for new sounds is so valuable—and why smart systems like Prelix aim to automate those boring, but impactful, observations.

Misalignment and coupling errors—the hidden force that destroys

Pumps are meant to be aligned. Proper coupling means both the driver and the pump rotor spin along the same line, smoothly, with no side forces. But in practice, slight misalignments slip in for all sorts of reasons: a rough installation, thermal expansion, or settling of a concrete base. Each leads to extra friction, bending forces, and vibration that wear down shafts, bearings, even seals.

- Misalignment often leaves no immediate trace—but it chews through component life remarkably fast.

- Vibration analyses tell the story after damage is already happening.

The real trick is that a once-perfect setup might shift imperceptibly, so routine checks and fast, accurate diagnosis are key. It’s another area where Prelix can help—using maintenance data to spot misalignment before it brings down an entire process line.

Conclusion—bringing hidden causes into the light

Most serious pump failures don’t start with a bang. They begin with a grain of sand, a bubble of vapor, a slightly loose bolt. The five hidden causes shared above wear away reliability, each adding their own silent risk. What’s truly challenging is their subtlety—how regular checks, even experience, sometimes aren’t enough to notice in time.

But it isn’t all gloom. By combining sharp observation, simple monitoring habits, and targeted data analysis with tools like Prelix, plant teams can catch trouble early, prepare stronger reports, and support better decision-making. Pumps, in the end, aren’t mysterious. Their stories can be read if you know how to look. If you’d like to see what’s really going on in your own maintenance routines—and make breakdowns less likely—get to know Prelix. Bringing hidden issues into the light is what we do best.

Häufig gestellte Fragen

What are common hidden pump failures?

Many pump failures begin with causes that are hard to notice: gradual component wear, internal contamination, cavitation, problems with seals or bearings, and minor misalignment of parts. Often, you can’t spot them easily from outside, but their effects build up over time and eventually halt normal pump function. These silent problems account for a big share of unexpected production stops in industrial settings.

How to identify pump failure causes?

Detecting hidden failures usually calls for a mix of experience, routine inspections, and smarter monitoring tools. Check performance data for slow changes, measure vibration, listen for odd noises, and analyze operation logs for strange patterns. Modern platforms like Prelix speed up the process by highlighting small trends and automatically suggesting which underlying causes might be at work. Sometimes, a combination of small clues tells the true story.

What signs show pump problems early?

Watch for new noises, changes in vibration, leaks around seals, inconsistent pressure, longer startup times, or a drop in throughput. Even a slight temperature change in bearings or oil can hint something is shifting inside. Most early signs are subtle, which is why comparing current and past data, or using trusted monitoring software like Prelix, helps catch small issues before they turn big.

How to prevent industrial pump failures?

Start with routine inspections, lubrication schedules, and regular replacement or cleaning of filters and seals. Analyze the fluid for contamination, keep an eye on alignment after installation, and listen for changes in sound during operation. Using smart monitoring and diagnostic platforms, such as Prelix, allows real-time identification of risk factors, so teams can address issues before an actual failure occurs.

What to do if pump fails?

First, shut down the affected pump safely to avoid extra damage or risk. Investigate the root cause by examining recent data, fluid samples, seal and bearing condition, and alignment. Document findings for compliance and planning. Using support from Prelix can streamline post-failure diagnostics, help you produce accurate reports, and direct you to the real root cause—making sure you learn from this failure and reduce future downtime.